Thin Film Deposition Systems

For thin-film deposition, the facility contains two systems. The first is a sputtering system ATC-2000F purchased from AJA International. The system contains 4 magnetron sputtering guns (2 DC and 2 RF) which allow in-situ tilting of their heads without breaking vacuum. This permits the user to optimize either uniformity or rate at any working distance in a very short amount of time without venting, resetting the angle, pump down and test. The system can handle substrates up to 4 inches in diameter and the substrate holder will allow simultaneous rotation, heating, RF bias and deposition at up to 850 °C in suitable sputtering environment (600 °C in a pure Oxygen environment). A load-lock chamber and cassette allows the samples to be removed and changed without venting the chamber. The cassette can hold up to 6 substrates holders.

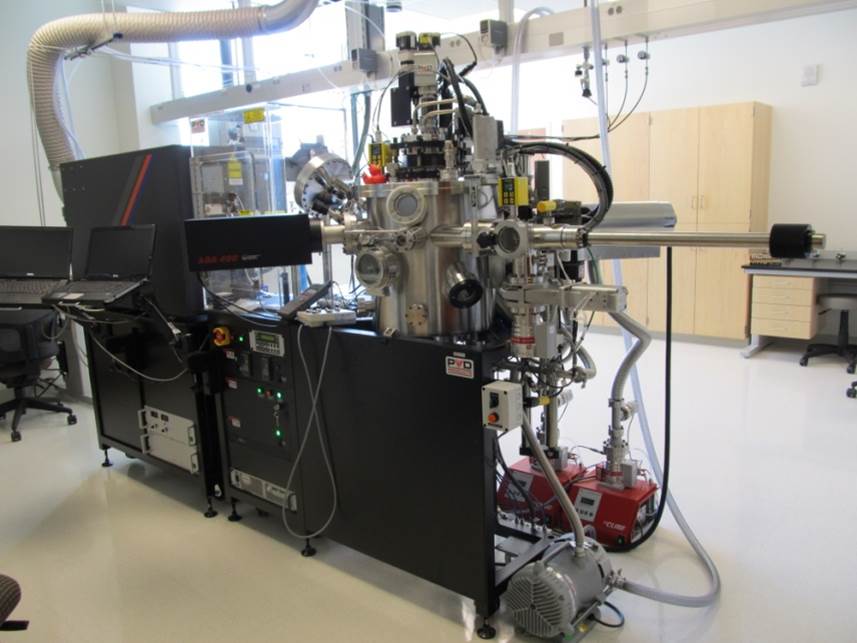

The second system is a Pulsed Laser Deposition system PLD-MBE 2500 from PVD Products. The PLD system has a target manipulator that handles six 2-inch diameter targets. Targets are held in pedestals by gravity so target clamping is not required. The system will allow simultaneous rotation of target and substrate. The system allows for in situ heating up to 950 °C and RHEED measurements.

Bulk sample preparation

The facility also maintains several systems to prepare samples in bulk quantities. The facility has a Materials Research Furnaces Inc. Arc Melting Furnace ABJ-338. The system is a complete, water-cooled, turn-key system for sustained high-temperature use with safety water flow interlock, safety insulated bellows, evacuation/gas system, and a 100% duty cycle power source. The ABJ-338 allows applications such as high-purity melts, creating alloys, powder melting, annealing, and material densification. Next is an Edmund Bühler GmbH Melt Spinner SC which is designed for laboratory applications and can produce up to 10 g of sample per run. The SC has a copper spinning wheel of 200 mm for a maximum surface velocity of 60 m/sec. It processes a small vacuum chamber which is compatible with a high-vacuum pumping system and low power generator. Finally, the facility also has a Fritsch Pulverisette 7 ball-milling system which is simple and safe to operate. The Pulverisette 7 can handle speeds ranging from 100-1100 rpm and is suitable for materials that are hard, medium-hard or brittle. The Pulverisette 7 ball mill offers an effective method to synthesize novel and nanosized materials.

Heat Treatment Ovens

Two tube furnaces (Lindberg 54233 and Lindberg 55332) together with vacuum pump stations are available for sample (or target) annealing, doping, and sintering. The Lindberg 54233 oven has an operating temperature of Tmax = 1500°C and a working tube of diameter 2". The Lindberg 55322 oven has an operation temperature of Tmax = 1200°C and a working tube of diameter 2.5". Both ovens have programmed power supplies and the base pressure of the pump stations are about 2 x 10-6 Torr.