X-ray photoelectron spectroscopy (XPS) is a surface analytical technique, which is based upon the photoelectric effect and measures the elemental composition, empirical formula, and chemical state of the elements within a material. XPS spectra are obtained by irradiating a solid surface with a beam of X-rays (Al Ka with an energy of 1486.6 eV) while simultaneously measuring the kinetic energy of photoelectrons that are emitted from the top 1-10 nm of the material being analyzed. Since the core-level XPS peaks for different elements appear at particular characteristic energies, the energies and intensities of the XPS peaks enable the identification and quantification of all elements from the surface (except hydrogen). Similarly, the chemical shifts and appearance of other special features, for example satellite and plasmon-loss peaks, in the XPS spectra are useful for chemical state analysis.

XPS has various scanning options: (i) Point scan: the spot size of the x-rays can be varied from 30 to 400 mm in 5 mm steps; (ii) Line and area scans are also possible with a maximum spatial resolution of 30 mm or better; (iii) K-alpha+ XPS is also capable of mapping the surface with a maximum spatial resolution of 30 mm or better and this is useful in understanding the elemental distribution across a surface.

A few other key features of the K-alpha+ XPS are also given below:

Charge Compensation: If the surface of a material is electrically insulating, then the emission of photoelectrons causes a positive charge to accumulate at the surface. This causes the XPS peaks to shift to high binding energies. The charge on the surface can be neutralized by replenishing electrons from an Ar-ion flood source during the measurement.

Depth Profiling: XPS also has an Ar ion beam for depth-profiling measurements (beam energy: 0.1 to 4 keV, current < 4 mA). This is helpful in etching away the surface contamination and also to investigate subsurface information. Combining a sequence of ion-gun etch cycles with XPS analyses provides quantified information as a function of layer thickness.

Angle-resolved XPS (ARXPS): We also have a sample holder that can be tilted for performing ARXPS. ARXPS enables electron detection from different depths by varying the emission angle at which the electrons are collected. Such measurements are non-destructive and can be applied to films that are too thin to be analyzed by conventional depth-profiling techniques or films that are irretrievably damaged by sputtering (e.g., polymers).

Ultraviolet Photoelectron Spectroscopy (UPS) operates on the same principle as XPS, but ultraviolet (UV) radiation is used to induce the photoelectric effect. UV photons are produced using a gas discharge lamp, typically filled with helium and have energies of 21.2eV (He I) and 40.8eV (He II). As lower energy photons are used, spectral acquisition is limited to the valence-band region. UPS can precisely measure the Fermi edge, density of states in the valence band, and electronic work function of a material being investigated.

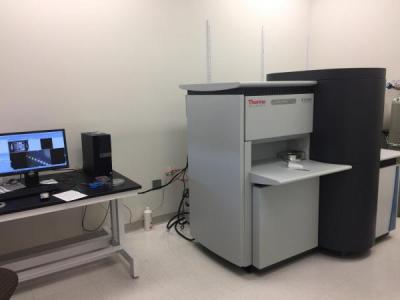

The Thermo Scientific K-alpha+ XPS/UPS system is user friendly and Avantage software allows complete instrument control, data acquisition, and data processing. Samples/specimens should be in solid forms such as thin films, powders, pellets, fibers, etc. Please contact Dr. Steve Michalski (smichalski@unl.edu) for further information and training.