Helpful Links

About the Facility

The Central Facility for Nanomaterials & Thin Films provides state-of-the-art instruments for fabricating material samples and devices. The primary focus of the facility is on nanostructuring by using thin film deposition and multi-layering. The facility has 3 thin film deposition systems which can deposit sub nanometer thick films in which 2 or more materials can be layered together in different order to form a multilayer structure. The properties of such samples or devices will depend on the actual intrinsic property of the nanostructuring such as how the materials interact through the interfaces. The facility also provides systems to alloy materials together to study the bulk material properties.

acknowledgement

Acknowledgement Text

Agencies including NSF and the University providing partial support of our Nebraska Nanoscale Facilities and NCMN Facilities require that the following words be included at the end of any Acknowledgement section of a paper in which experimental work was done in NNF-NCMN facilities:

The research was performed in part in the Nebraska Nanoscale Facility: National Nanotechnology Coordinated Infrastructure and the Nebraska Center for Materials and Nanoscience (and/or NERCF), which are supported by the National Science Foundation under Award ECCS: 2025298, and the Nebraska Research Initiative.

Equipment

Equipment

Thin film Systems

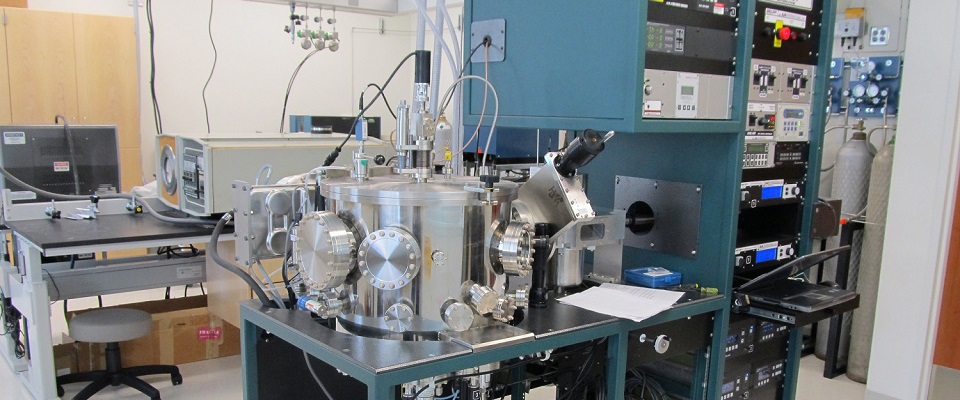

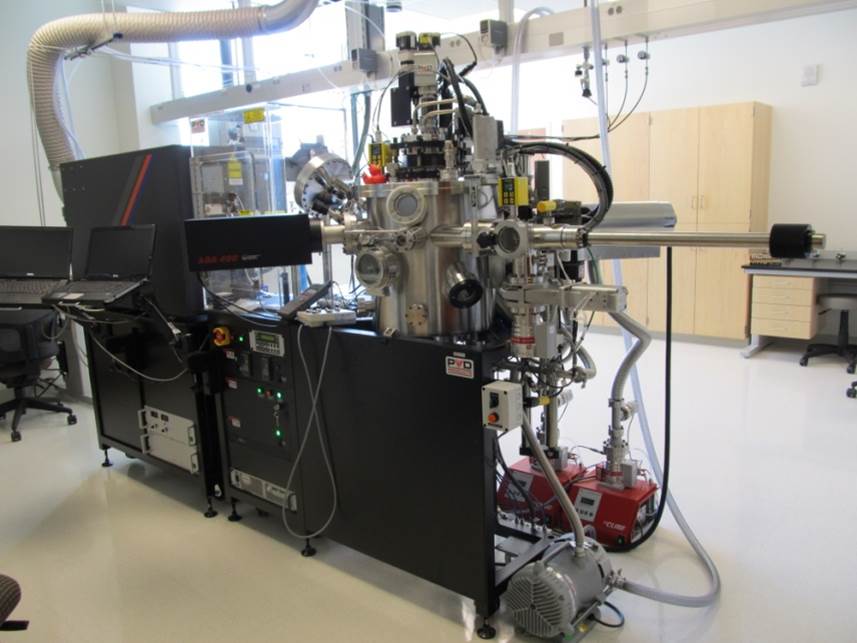

For thin film deposition the facility contains 2 systems. The first is a sputtering system ATC-2000F purchased from AJA International. The system contains 4 magnetron sputtering guns 2 DC and 2 RF which allow in-situ tilting of their heads without breaking vacuum. This permits the end user to optimize either uniformity or rate at any working distance in a very short amount of time without venting, resetting the angle, pump down and test. The system can handle substrates up to 4 inches in diameter and the substrate holder will allow simultaneous rotation, heating, RF bias and deposition at up to 850 °C in suitable sputtering environment (600 °C in a pure Oxygen environment). A load lock chamber and cassette allows the samples to be removed and changed without venting the chamber. The cassette can hold up to 6 substrates holders. The second system is a Pulsed Laser Deposition system PLD-MBE 2500 from PVD Products. The PLD system has a target manipulator that handles six 2-inch diameter targets. Targets are held in pedestals by gravity so target clamping is not required. The system will allow simultaneous rotation of target and substrate. The system allows for in situ heating up to 950 °C and RHEED measurements.

Precious Metal Usage

The facility provides a Gold and a Platinium target which can be used in the deposition systems in the facility. Users weigh the target before and after use and are charged for the material used. The facility also has other targets (such as Cr, Al, Zn, Si, SiO2 and Cu) which were left by users leaving and retiring. These targets can be used free of charge. Note, the facility does not purchase targets for users.

Heat Treatment Ovens

The facility also has two tube furnaces. The Lindberg 55322 oven is a Split-Hinge Single Zone Furnace with a Tmax = 1200 °C and a working tube of diameter 2.5 inches. And the MTI 1700 tube oven has an operating temperature of Tmax = 1700 °C and a working tube of diameter 2 inches. Both ovens have programmable power supplies/temperature controllers and associated pump stations that can reach a base pressure 5 x 10-6 Torr. Applications include ashing, sintering, crystallizing, annealing, etc. The tube furnaces are used for crystal growth because of their small volume and precision with which the temperature can be controlled. The ends of the tubes do not get very hot and various adapters may be placed on the ends. This permits reactions under controlled atmosphere using reactive/un-reactive gases or a vacuum.

Bulk sample preparation

The facility also maintains several systems to prepare samples in bulk quantities. The facility has a Materials Research Furnaces Inc. Arc Melt Furnace ABJ-338. The system is a complete, water-cooled, turn-key system for sustained high temperature use with safety water flow interlock, safety insulated bellows, evacuation/gas system, and a 100% duty cycle power source. The ABJ-338 allows applications such as high purity melts, creating alloys, powder melting, annealing, and material densification. Next is an Edmund Bühler GmbH Melt Spinner SC which is designed for laboratory applications and can produce up to 10 g of sample per run. The SC has a copper spinning wheel of 200 mm for a maximum surface velocity of 60 m/sec. It processes small vacuum chamber which is adequate for high-vacuum pumping system and low power generator. Finally, the facility also has a Fritsch Pulverisette 7 ball mill system which is simple and safe to operate. The Pulverisette 7 can handle speeds ranging from 100-1100 rpm and is suitable for materials which are hard, medium-hard or brittle. The Pulverisette 7 ball mill offers an effective method to synthesize novel and nanosized materials.

Users of the facility

The Facility is accessible to all qualified researchers at UNL, at other universities and in industrial and other laboratories on payment of the appropriate charges. All users are required to take all appropriate safety training from the University Environmental Health and Safety (EHS). Also, users are required to obtain appropriate training and instruction specific for each instrument from the facility specialist. Users must demonstrate sufficient proficiency before and during equipment usage for training to be completed.

University and NCMN policy requires users to acknowledge the NCMN in their publications. An example of such an acknowledgement is as follows: “This work was performed in part in Facilities of the Nebraska Center for Materials and Nanoscience which is supported by the Nebraska Research Initiative.”

Most instruments require reservation in advance of use. In the unlikely event that equipment is simultaneously needed by more than one researcher, members of the UNL community receive priority.