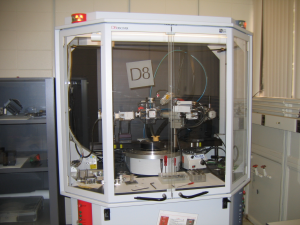

Bruker-AXS D8 Discover with Vantec 500 Area Detector

Overview

This instrument is a state-of-the-art multi-purpose X-Ray Diffractometer (XRD) system which is located in the Nebraska Center for Materials and Nanoscience (NCMN) X-Ray Materials Characterization Facility.

Common configurations are available for review.

This system includes the following highlighted hardware:

- Vantec 500 area detector:

Large area, high sensitivity, 2-dimensional detector based on MikroGap technology allows collection of a large quantity of 2-Dimensional information in a small amount of time. - Centric 1/4-Circle Eulerian Cradle

Sample positioning: motorized Chi(tilt) and Phi(rotation) rotations and X-Y-Z translations. The cradle accommodates bulky specimens, powders, thin-films, and wafers up to 80 x 50 x 20 mm and weighing up to 1 kg. - Domed hot stage

Heating device with an x-ray transparent dome designed for orientation sensitive temperature studies from room temperature to 900 °C in air, vacuum, or inert gas atmosphere. It allows access to the entire diffraction space of a sample when measuring in reflection mode. - Hi-flux in plane hardware:

Unique hardware allows x-ray tube to be rotated such that the line-focus is in the scattering plane of the instrument which produces very high diffracted intensities when in the grazing incidence in-plane diffraction geometry. Motorized tube movement out of the diffractometer scattering plane allows accurate setting of incident angle. - Laser/video Sample alignment System:

Computer controlled video camera and laser pointer for easy and accurate sample positioning and system alignment. - Göbel Mirror

A parabolic, laterally graded multilayer mirror which converts the divergent beam projected by the line focus of an x-ray tube into a quasi-monochromatic and highly parallel (divergence .03°) beam of high intensity. White radiation and Kα lines are virtually eliminated. - V-Groove Ge crystal monochromator

Using the Göbel mirror as a beam conditioner, this channel cut 2-bounce Germanium monochromator yields a beam that is extremely parallel (divergence .007°) and monochromatic (only Cu Kα1) for high resolution applications. - Fine Tilt stage

Motorized tilt stage for sample pre-alignment allows tilting of a sample around 2 perpendicular axes which allows orientation of sample normal to coincide with the Phi-circle of the Eulerian cradle. - Dual Beam Path analyzer module

Motorized module that allows software controlled switching between 2 diffracted-beam configurations. The first is a high intensity path incorporating a motorized slit, and the second is a high-resolution path incorporating a triple-bounce channel-cut monochromator.

The system can be reconfigured for the following applications:

- Grazing Incidence In-Plane XRD (GIIXD)

In-plane diffraction is a technique for measuring the crystal planes that are oriented perpendicular to the surface. As a result, the in-plane lattice parameters and crystal orientation can be determined. - Grazing Incidence XRD (GIXD)

Enhance diffracted signal from polycrystalline thin films and examine structural variations as a function of depth by precisely controlling incident angle and therefore the penetration depth of x-rays. - X-Ray Reflectivity (XRR)

Measures film thickness, roughness (interface and surface), and density of films (2 nm – 500 nm). Also measures multilayer interface quality and periodicity structure evaluation. - High-temperature, orientation sensitive XRD

Temperature-induced phase transition investigations, texture measurements, stress, profile analysis, powder diffraction, grazing incidence, and high resolution studies. Point detector can be used for high resolution or area detector for high speed. - High-Resolution XRD (HRXRD)

Rocking Curves This is a method for analyzing epitaxial structures for which the layer and substrate are almost perfect single crystals. These means the difference in diffraction angle for the layer and substrate is very small and requires the capability to resolve Bragg peaks on an arc second scale. The data is recorded as a rocking curve and can be modeled and fitted to reveal structural details of the epitaxial layer.

Reciprocal Space Maps This is a technique for analyzing epitaxial (and similar) thin films. Narrow scans of reciprocal lattice points are performed for various diffractometer settings and the scattered intensity can be plotted in a 2-dimensional frame. - Texture (pole figures)

A pole figure is measured at a fixed scattering angle (constant d spacing) and consists of a series of Phi-scans (in- plane rotation around the center of the sample) at different tilt or Chi angles and measures preferred crystallite orientation. Measurement times are much faster when using the Hi-Star area detector. - Residual stress

Stress is determined by recording the angular shift of a given Bragg reflection as a function of sample tilt (psi). This actually provides a measure of strain in the sample from which the stress can then be calculated by plotting the change in d-spacing against sin2psi. This measurement is faster and more accurate when calculations are based on the distortion of the entire Debye ring which is possible when using the Hi-Star area detector. - Microdiffraction and capillary diffraction

Small sample amounts, and/or samples which tend to have texture can be prepared in thin glass capillaries. A fast, reliable diffraction pattern can be acquired when the signal is detected over a large portion of the solid angle with an area detector. Small areas on larger samples can be probed using this method with the laser/video sample alignment and sample positioning of the Eulerian cradle.