SMCF Home

Helpful Links

SMCF Updates

Procedures for Entering SMCF:

Users will need to follow the safety guidelines on COVID-related protocols and procedures. We will require you to wear a face mask, use hand sanitizer when you enter the lab, and practice social distancing while in SMCF. This is to assure the safety of everyone working in our Labs. This procedure is subject to change per state/university restrictions.

Protect yourself and others! Thank you for your patience and understanding!

About the Facility

The Surface and Materials Characterization Facility (SMCF) provides state-of-the-art instruments for nanometer-scale surface measurement, thermal analysis, and mechanical characterization of a variety of materials.

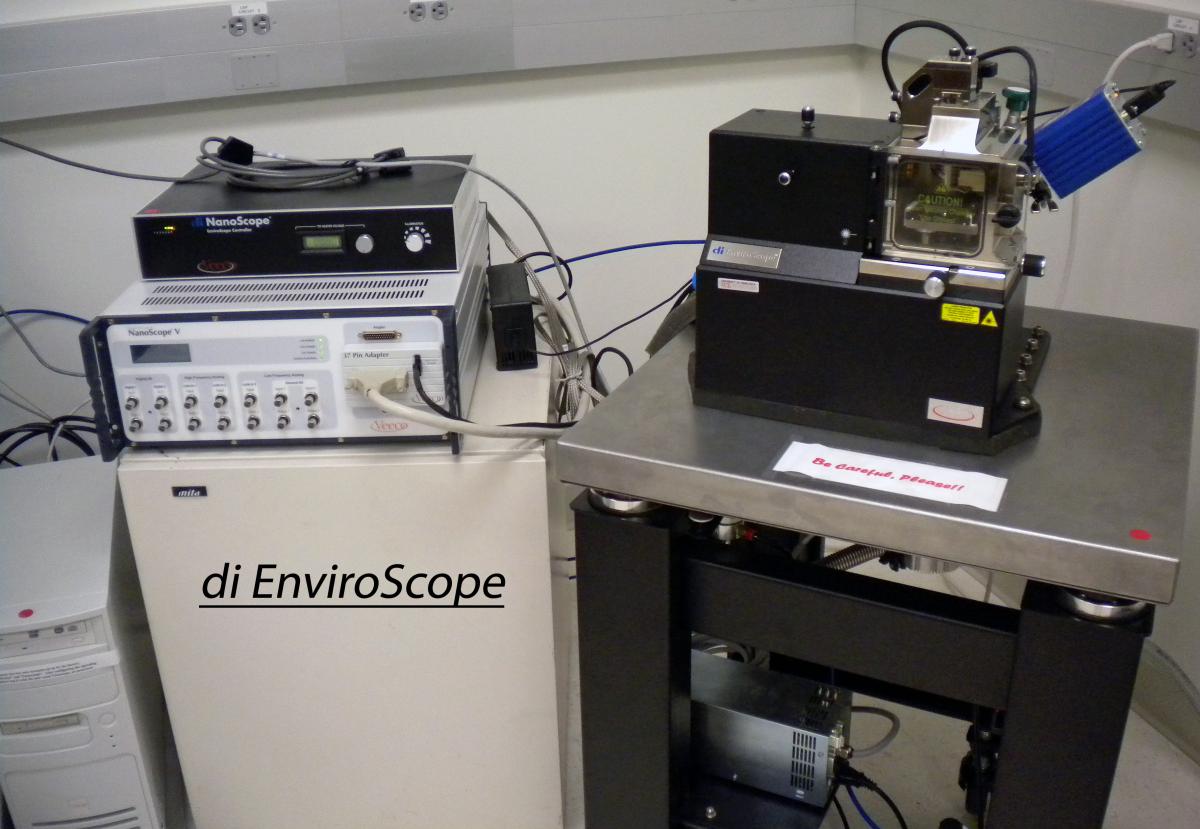

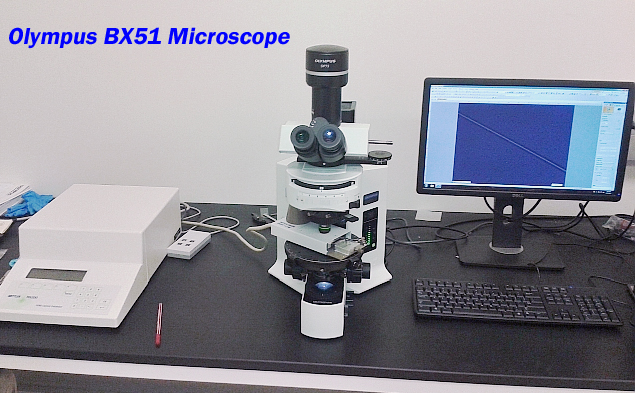

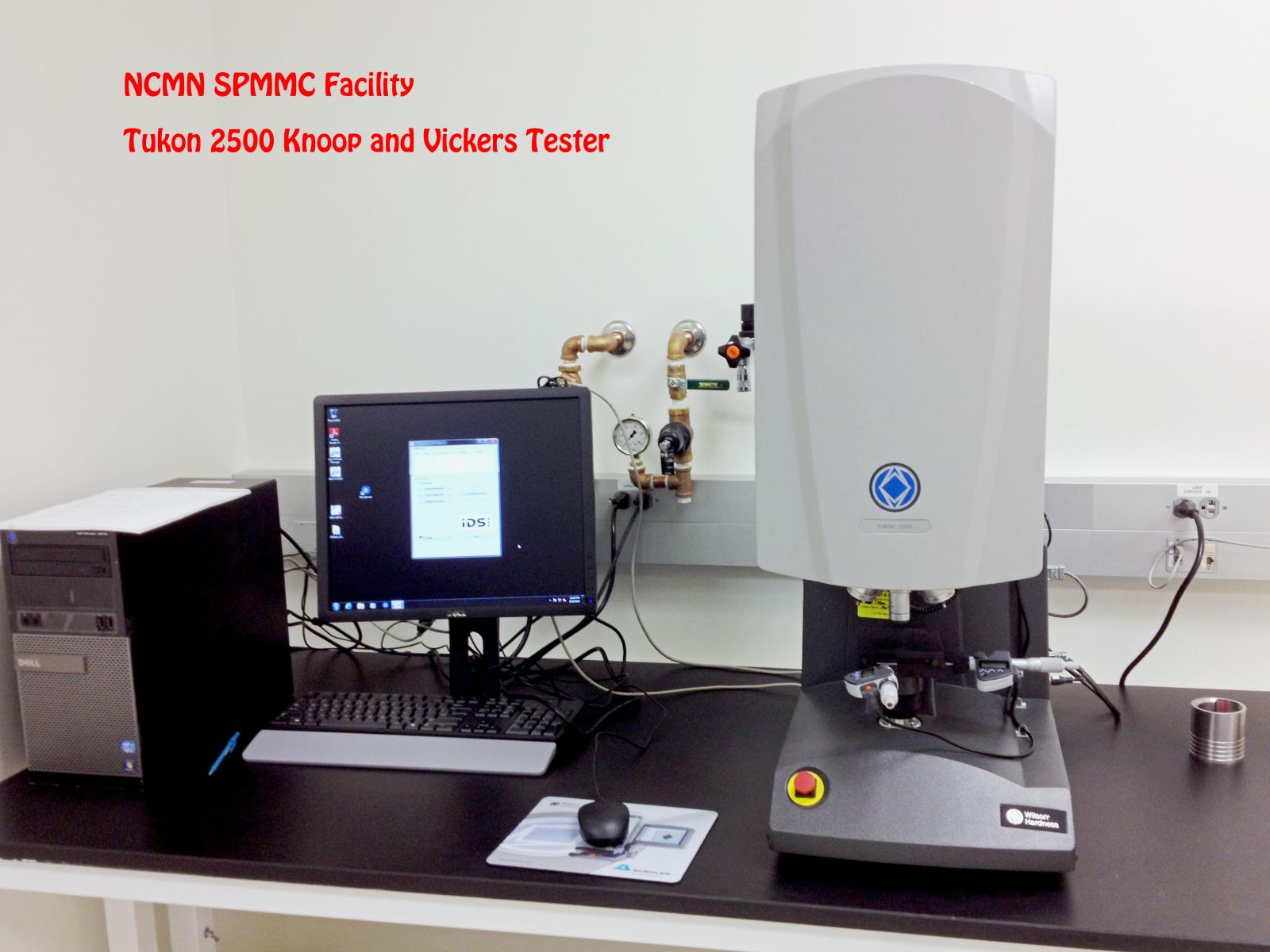

The SMCF facility is currently defined in three areas (bays) as scanning probe microscopy, thermal and optical analysis, and mechanical characterization and sample preparation. The scanning probe microscopy (SPM) bay contains four SPM microscopies, including ATTOCUBE SPM, BRUKER ICON SPM, EnviroScope Atomic Force Microscope, and Dimension 3100 SPM system. The SPM offers simultaneous high-magnification observation of 3D images and related physical properties, as well as measurements in various environments. Two thermal analysis systems: a differential scanning calorimeter (DSC 204 F1 Phoenix) and a thermogravimetry analysis system (TGA 209 F1 Libra) allow users to study and measure various thermal properties of materials such as glass-transition, melting, and crystallization temperatures. Also available is an Olympus BX51 polarizing optical microscope which includes a Mettler Toledo FP900 thermal system equipped with an FP 82 hot stage with a temperature range from room temperature to 375° C. The mechanical characterization and sample preparation bay houses the following: (1) Tukon 2500 Knoop/Vickers Hardness tester, (2) BUEHLER ISOMet 1000 Precision Saw, (3) BUEHLER MiniMet 1000 Grinder-polisher, and (4) Sartorius Cubis MSU2.7S-000-DM Microbalance.

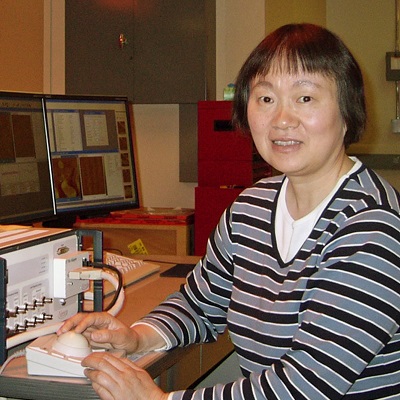

The SMCF Specialist, Dr. Lanping Yue is in charge of the SMCF central facility to maintain equipment, as well as to teach and assist users in the use of these instruments, analysis techniques and data interpretation and presentation. Research collaborations are welcome from all university research groups, as well as companies in Nebraska and elsewhere.

Acknowledgment Text

Agencies including NSF and the University providing partial support of our Nebraska Nanoscale Facilities and NCMN Facilities require that the following words be included at the end of any Acknowledgement section of a paper in which experimental work was done in NNF-NCMN facilities:

The research was performed in part in the Nebraska Nanoscale Facility: National Nanotechnology Coordinated Infrastructure and the Nebraska Center for Materials and Nanoscience (and/or NERCF), which are supported by the National Science Foundation under Award ECCS: 2025298, and the Nebraska Research Initiative.

Equipment

- AttoAFM with AttoDRY2100 Cryostat and 9T Superconducting Magnet

A state-of-the-art multifunctional low-temperature high-magnetic field scanning probe microscopy (LTHM-SPM) system was installed in NCMN-SMCF recently for nanoscale science and engineering research.

This LTHM-SPM is capable of characterizing spatially resolved conductivity (c-AFM), magnetic force (MFM), piezoresponse (PFM), and topography (AFM) down to the nanoscale.

The unique capabilities of the LTHM-SPM system are imaging various physical properties over a wide temperature range (4 -300 K), and magnetic field range (0-9 T). It will be a powerful tool for materials investigations.

The Bruker Dimension Icon® Atomic Force Microscope is equipped with a ScanAsyst® automatic image optimization mode based on PeakForce Tapping technology, which enables users to obtain consistent high-quality results easier and faster. This system is capable of many SPM applications as follows:

- Contact mode, tapping mode, peakforce tapping mode AFM, and AFM in fluid for surface topography imaging;

- Magnetic Force Microscopy (MFM) - magnetic force gradient detection;

- Electrostatic Force Microscopy (EFM) - measures variation in the electric field gradient above a sample;

- Kelvin Probe Force Microscopy (KPFM) - measures material work function as well as surface charge;

- Scanning Tunneling Microscopy (STM) - primary highest resolution AFM mode;

- Tunneling Current AFM (TUNA) - measures a material’s electrical conductivity with a wide range of currents from 100 fA-1 uA;

- Piezoresponse Force Microscopy (PFM) - studies piezo materials at the nanoscale;

- Quantitative Nanomechanical Property Mapping (PF-QNM) - enabling researchers to map and distinguish quantitatively between nanomechanical properties while simultaneously imaging sample topography at high resolution. This technology operates over an extremely wide range (1MPa to 50GPa for modulus and 10pN to 10μN for adhesion) to characterize a large variety of sample types.

- Execute temperature control and thermal analysis on samples from 25°C to 200°C while scanning in some SPM modes.

- EnviroScope Atomic Force Microscope (ESCOPE)

The Digital Instruments EnviroScope combines AFM imaging with environmental controls and a hermetically sealed sample chamber to perform Contact Mode and TappingMode atomic force microscopy in air, vacuum, or a purged gas, as well as a heated environment. With advanced environmental capabilities, users can observe sample reactions to a variety of complex environmental conditions while scanning.

- Dimension 3100 SPM System

The Digital Instruments Nanoscope IIIa Dimension 3100 SPM system provides 3D images for a large variety of materials, such as nanoparticles, polymers, DNA, semiconductor thin films, magnetic media, optics and other advanced nanostructures.

AFM can provide three-dimensional high contrast topographic images with sub-nanometer resolution including line width, grain size, thin film thickness, roughness measurements, sectioning of surfaces, particle analysis, surface defects, and pattern recognition, etc.

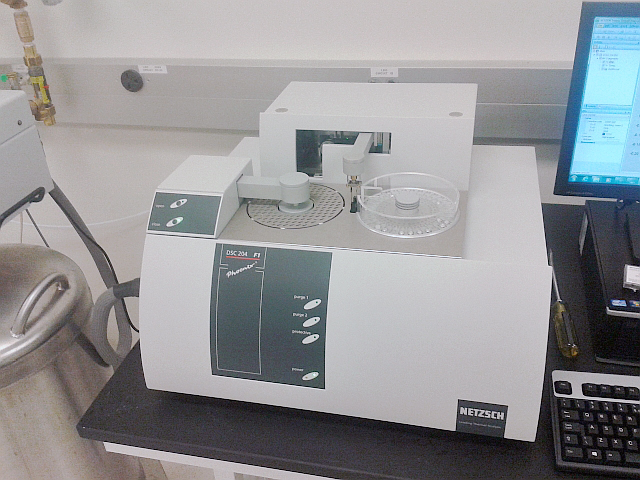

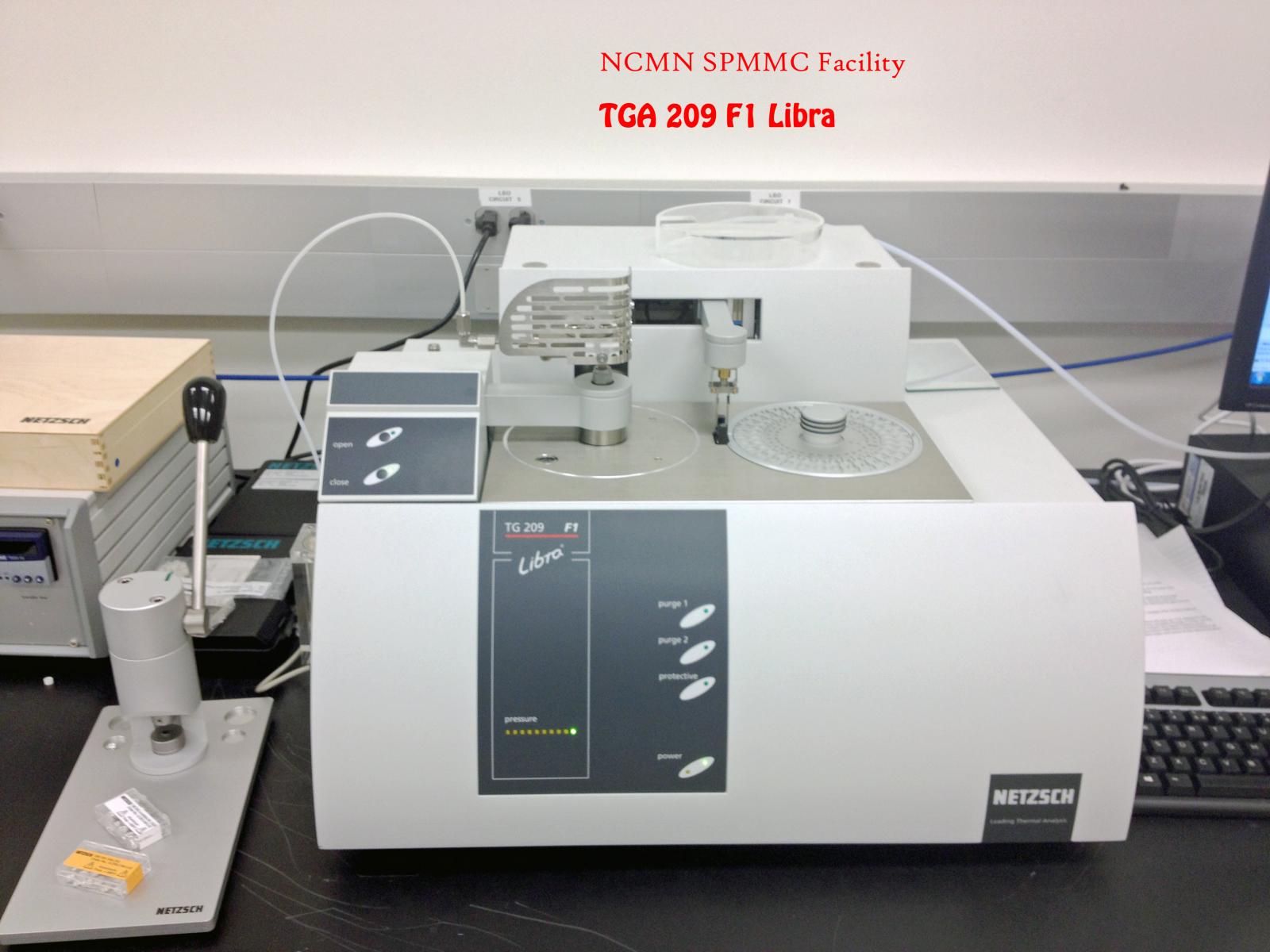

- DSC and TGA Thermal Analysis Systems

The SMCF facility has two thermal analysis systems: a differential scanning calorimeter (DSC 204 F1 Phoenix) and a thermogravimetry analysis system (TGA 209 F1 Libra). Both systems operate through a large temperature range from -170°C to 600°C for the DSC, and 25°C to 1100°C for the TGA. These systems allow users to study and measure various thermal properties of materials such as; glass-transition temperatures, melting temperatures, melting enthalpy, crystallization temperatures, crystallization enthalpy, transition enthalpies, phase transformations, phase diagrams, and other thermal properties.

- Olympus BX51 Polarizing Microscope

The SMCF houses an Olympus BX51 optical microscope, which includes polarizing microscope capabilities for sample viewing and image analysis in transmission and reflection modes. In addtion, the thermal behavior of materials can be observed under the microscope with a Mettler Toledo FP900 thermal system equipped with an FP 82 hot stage (temperature range from room temperature up to 375° C).

Vickers/Knoop Hardness Tester measures the mechanical hardness of materials. The Vickers/ Knoop microhardness test is used particularly for small parts, very brittle materials, or thin sheets, where only a small indentation may be made for testing purposes. The test force range: 10 g to 1000g. Hardness testing involves using a known load and a known indenter shape which is then pressed into a material. The depth of penetration of the indenter is proportional to the hardness of the material. Hardness data can be used to infer other mechanical properties of the material.

- ThermoFisher K-Alpha XPS/UPS Photoelectron Spectrometer

Please contact Dr. Steve Michalski (smichalski@unl.edu) for further information and training.

- Other Equipment

- Buehler ISOMet 1000 Precision Saw

-

The IsoMet 1000 Precision Saw offers increased speed, load, and a 7-inch diamond blade capacity that enables a wide variety of advanced materials to be cut quickly and with low deformation.

- Buehler MiniMet 1000 Grinder-polisher

-

The MiniMet 1000 Grinder-polisher is a sample preparation system with adjustable speed and high-pressure capability that quickly prepares materials (such as ceramics, composites, and metals) for cross-sectional analysis.

- Sartorius Cubis MSU2.7S-000-DM Microbalance

-

Microbalance with a readability of 0.0001 mg is a high-resolution measuring instrument used for measuring samples up to a 2.1 g weighing capacity.

Facility Contacts